RF Solutions

Phone: 01600 719464

- Products

- Nickel

- Copper

- Hybrid

- Compliant Silver

- Silver

- Decorative Polyurethane

- Decorative Epoxy

- Other Products

- Testimonials

-

Thanks from all of us again for the excellent customer service.

Senior Buyer - Fire Detection Systems

-

Can't believe the fuss this seems to have generated with some suppliers, like they've never seen this type of document! Thank you for your help.

Quality Manager - Cash Protection System

Copper

EMC Shield Copper Conductive Colloid RF2001-CC-C has been formulated to meet the strictest control of electrical interference both radiation and susceptibility. It is formulated with specially prepared silver-coated copper particles and conductive resins to provide a conductive layer when applied by RF Solutions, compatible on to plastic, resins and metal substrates for a wide range of products. The highly conductive shield RF2001-CC-C when applied to specification provides an effective shielding against radiated radio and Electromagnetic interference (RFI & EMI) and in other application can act as a ground plane to protect against electrostatic discharge (ESD).

Key Points

- Compatible with sensitive plastics

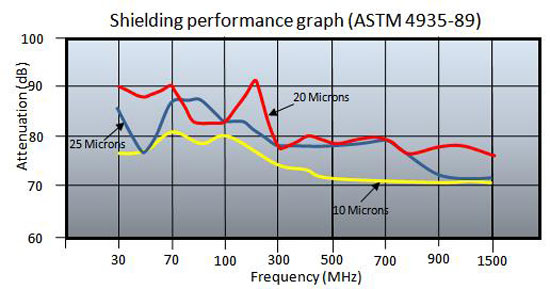

- Effective Shielding at 25 Microns dry film thickness

- Passes UL Environmental Requirements UL746C

- Excellent Adhesion and Cohesion

- Can be applied to most substrates Plastics, metals and some rubbers

- Excellent Abrasion resistance scuff resistant

- Bright copper in appearance.

- Standard adhesion cross hatch test to ASTM D-3359-97 requirements

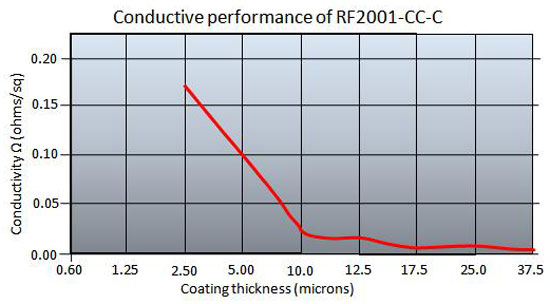

- Typical resistance at 25 microns dry film >0.015ΩOhms / sq.

- RCA Abrader passes 500+ Cycles @ 25 microns dry film

- Selective coating is achieved by using detailed masking

- COSHH, RoSH and REACH Compliant material

- Tested for long-term environmental stability to UL746C

- Temperature ageing 7 days exposure to 85 deg C @ 85% R.H.

- Temp Cycling – 10 cycles of, 75⁰C for 1hr, Ambient for 1hr & -30⁰C 1hr

- Humidity – 35⁰C for 56 days at 95% R.H.

- No degradation of properties after Environmental testing

This graph indicates the levels of performance of RF2001-CC-C over a frequency range up to 1.5 GHz to ASTM 4935-89 but has been tested up to 10 GHz to Military Standard MIL STD 285, typically 10 GHz protects at 78 dB plus.

This graph indicates the conductivity when testing sheet resistance to ASTM 254 ohms per square area and should be used in conjunction with point-to-point.